The goal of a flatness control is to have all points of a surface or all derived median points contained within a plane. The flatness tolerance zone is a pair of parallel planes separated by the specified flatness tolerance that will contain all points in the surface or all derived median points.

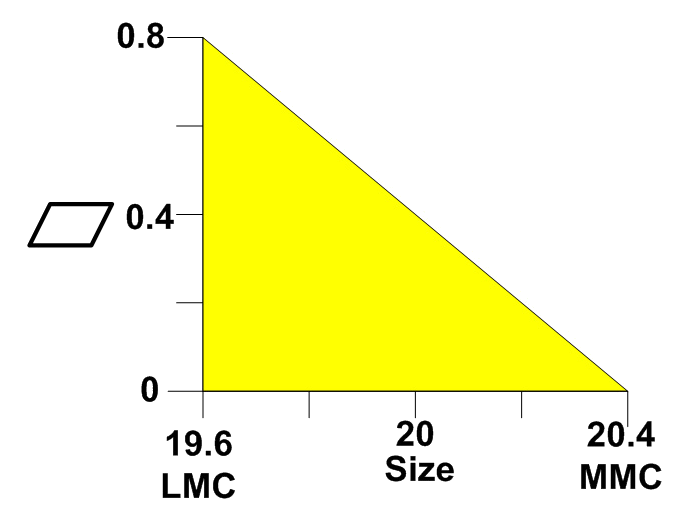

In this example, the 20 mm dimension defines a pair of parallel planes. According to Rule #1, this part must fit within an envelope of 20.4 and any two-point measurement may not be less than 19.6. If the part passes these size checks, the top and bottom surfaces as well as the derived median plane must be flat within 0.8.

The tolerancing diagram shows the amount each surface may be out of flat at any increment of size. If, for instance, the part is manufactured at the MMC limit of size (20.4), both surfaces would have to be perfectly flat. However, when the actual size of the feature is made smaller than MMC, the feature may meet the size requirements while allowing the surfaces to be out of flat by an amount equal to the difference in the actual size of the feature and the MMC size. If the feature is made at 19.6, in theory each of the surfaces and the derived median plane could be out of flat by as much as 0.8. In the real world the part will probably never be out of flat by more than 0.4, half the total size tolerance.

One way to improve the form of the surface is to add a flatness tolerance.

Flatness is often used to:

- control the primary datum feature to improve reproducibility of measurement

- reduce strain caused by clamping forces in assembly

- provide a flat surface for sealing

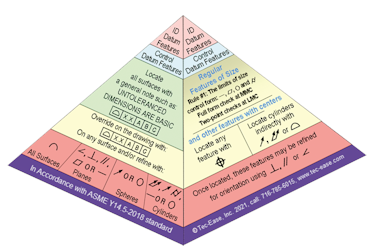

Usually flatness will be provided by some other tolerance. Following The GD&T Hierarchy, with the exception of controlling a planar primary datum feature, flatness should not be the first control applied to a feature.

Flatness is used to control the flatness of a surface better than the flatness control provided by:

- a size tolerance

- perpendicularity

- parallelism

- angularity

- profile of a surface

- total runout

To control a feature center plane better than the control provided by:

- a size tolerance

- other