This course is intended for those who already know GD&T in accordance with the ASME Y14.5-2009 Standard. This is not for someone who is new to GD&T. This training will present the revisions and updates found in the ASME Y14.5 2018 Revision of the Y14.5 Standard.

- Section 1: Introduction to The ASME Y14.5 Update

- Section 2: References

- Section 3: Definitions

- Section 4: Fundamental Rules, Tolerancing, Defaults and Dimensioning Practices

- Section 5: Tolerancing, Interpretation of Limits, Limits of Size, and Material Condition Modifiers

- Section 6: Symbology

- Section 7: Datum Reference Frames

- Section 8: Form

- Section 9: Orientation

- Section 10: Tolerances

- Section 11: Profile

- Section 12: Runout

Section 1 - Introduction to The ASME Y14.5 Update

Section 2 - References

Section 3 - Definitions

Section 4 - Fundamental Rules, Tolerancing, Defaults and Dimensioning Practices

Section 5 - Tolerancing, Interpretation of Limits, Limits of Size, and Material Condition Modifiers

Section 6 - Symbology

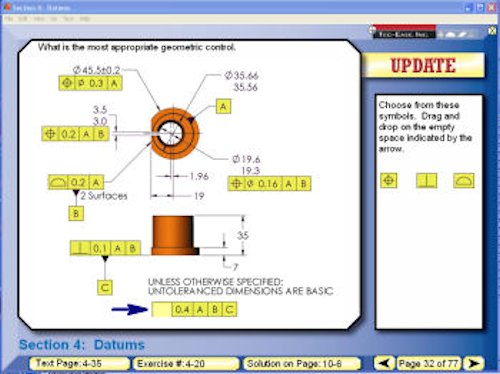

Section 7 - Datum Reference Frames

Section 8 - Form

Section 9 - Orientation

Section 10 - Tolerances

Section 11 - Profile

Section 12 - Runout