You may have been told in high school that: "Railroad tracks going around a mountain remain parallel, otherwise the train would jump the track."

Unfortunately, that description of parallelism does not quite agree with the ASME Y14.5 standard. The Standard tells us that features may be parallel to either a datum axis or a datum plane. Since parallelism must always be relative to a datum axis or plane, the surfaces shown below are not parallel per Y14.5.

They are equidistant at all points but since they are not equidistant to a datum axis or datum plane, according to the Standard, they are not parallel. They do have a constant actual local size. You might think of this as wall thickness or material thickness.

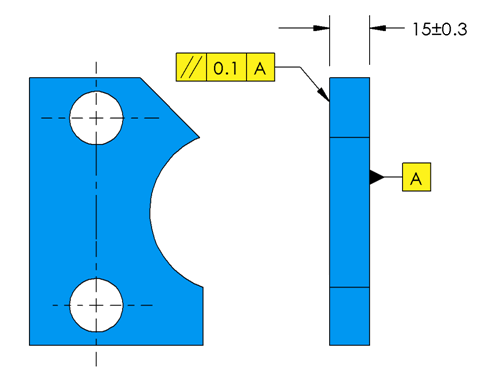

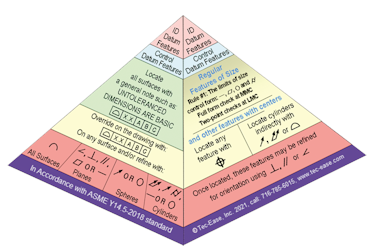

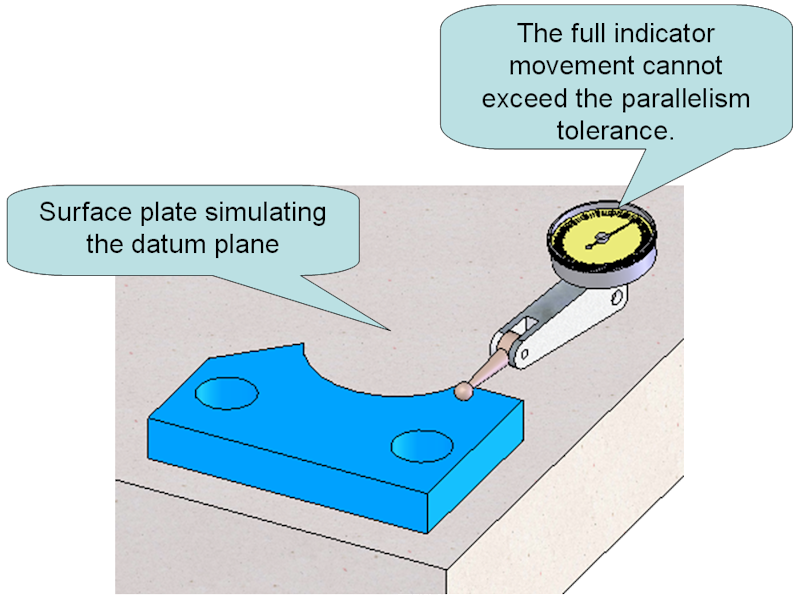

Parallelism is used to refine the parallelism control provided by size, profile of a surface or position. Parallelism is an orientation tolerance, therefore, it never locates the feature. When applied to a flat surface, it is like a flatness tolerance that is oriented at 0° to the referenced datum.

The most common applications of parallelism are to provide control of parallelism to a feature better than the parallelism control provided by:

- Size per Rule #1

- Position (applied to features of size)

- Profile of a surface

When parallelism is applied to a plane that is part of a feature of size and the other plane of that feature is the referenced datum feature, the parallelism tolerance cannot be greater than or equal to the size tolerance or it would be meaningless since the plane's parallelism is automatically controlled by the size dimension.